Rebuilding an engine is a complex yet rewarding process that requires precision, technical knowledge, and patience. This comprehensive engine rebuild tutorial will guide you through every critical stage of engine restoration, from initial disassembly to final reassembly, helping you transform a worn-out engine into a powerful, reliable powerplant. Whether you’re a professional mechanic or an ambitious DIY enthusiast, this guide provides the essential insights and techniques needed to successfully rebuild an engine.

What Are the Preliminary Preparations for Engine Rebuild?

Safety and Workspace Setup

Before diving into the engine rebuild tutorial, establishing a proper workspace is crucial:

- Workspace Requirements:

- Clean, well-ventilated area

- Adequate lighting

- Stable work surface

- Protective equipment (safety glasses, gloves)

Essential Tools Checklist

| Tool Category | Key Items | Estimated Cost Range |

|---|---|---|

| Lifting Equipment | Engine Hoist, Engine Stand | $300 – $800 |

| Measurement Tools | Micrometer, Bore Gauge | $100 – $300 |

| Disassembly Tools | Torque Wrench, Valve Spring Compressor | $100 – $250 |

How to Remove and Disassemble the Engine?

Systematic Engine Removal Process

- Battery Disconnection

- Disconnect negative and positive terminals

-

Label and secure battery cables

-

Fluid Drainage

- Drain engine oil

- Remove coolant

-

Capture fluids in appropriate containers

-

Component Disconnection

- Remove accessories (alternator, power steering pump)

- Disconnect electrical connections

- Label all wiring and hoses

Detailed Disassembly Techniques

Top-End Disassembly

- Remove valve covers

- Extract cylinder heads

- Carefully remove valvetrain components

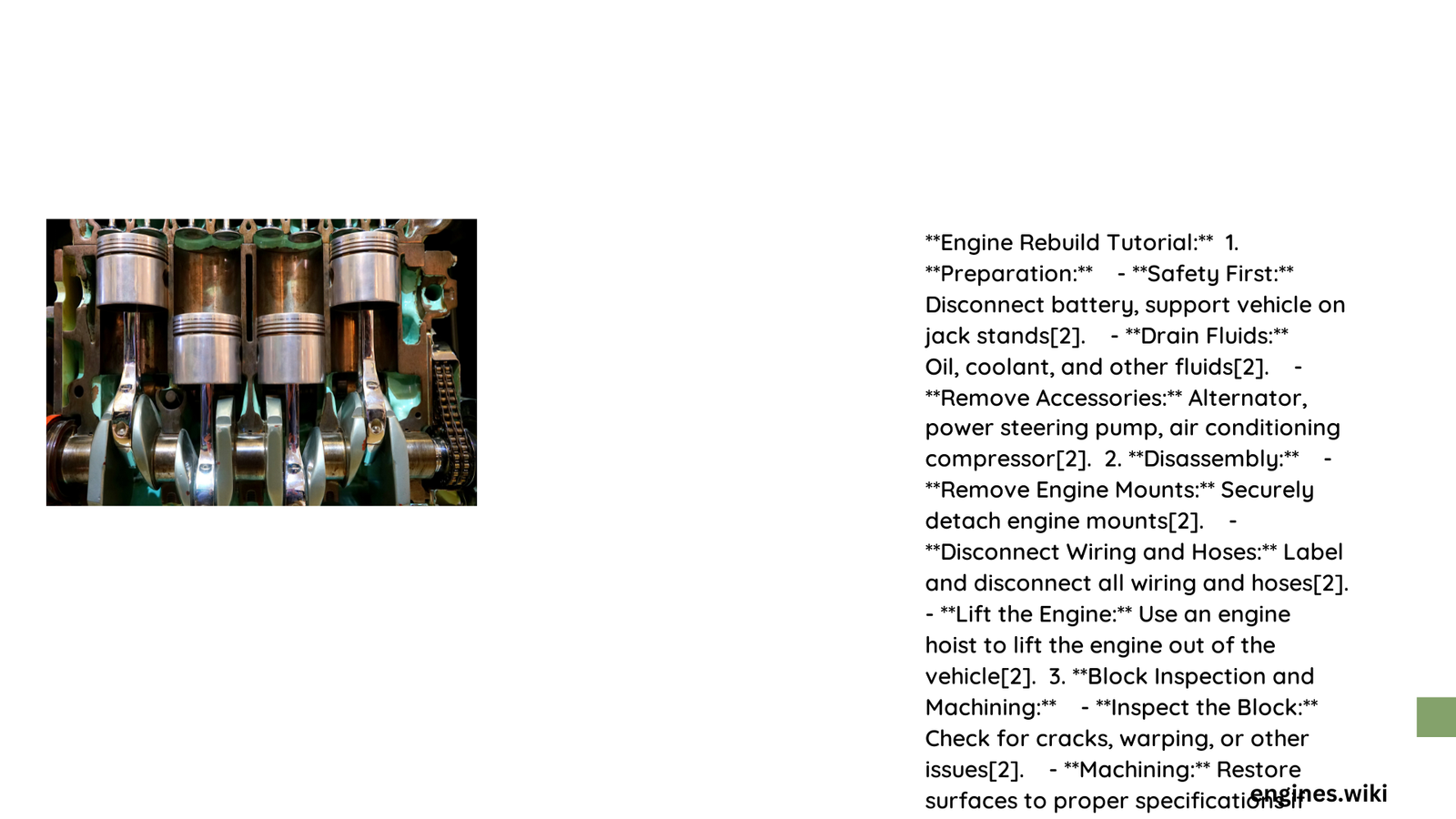

Bottom-End Disassembly

- Remove connecting rod caps

- Extract pistons

- Carefully remove crankshaft

What Are Critical Inspection and Machining Steps?

Comprehensive Engine Block Evaluation

Inspection Criteria:

– Check for cracks

– Measure cylinder bore dimensions

– Assess surface flatness

– Evaluate bearing surfaces

Machining and Restoration Techniques

- Cylinder Honing

- Surface Resurfacing

- Crack Repair

- Component Replacement

How to Reassemble the Engine?

Precise Reassembly Methodology

- Lubrication Preparation

- Apply assembly lubricant

-

Ensure proper component coating

-

Crankshaft Installation

- Install main bearings

- Set crankshaft alignment

-

Torque main caps sequentially

-

Piston and Ring Installation

- Check ring end gaps

- Install pistons with proper orientation

- Use ring compressor for smooth insertion

What Are Potential Rebuild Challenges?

Common Rebuild Complications

- Incorrect Torque Specifications

- Improper Cleaning

- Misalignment Issues

- Component Compatibility

What Are the Cost Considerations?

Rebuild Cost Breakdown

| Cost Category | Estimated Range |

|---|---|

| Parts | $2,000 – $6,000 |

| Labor | $2,000 – $5,000 |

| Machine Work | $500 – $1,500 |

Final Recommendations

- Always follow manufacturer specifications

- Invest in quality tools

- Take detailed documentation during disassembly

- Be patient and methodical

Pro Tips

- Use digital photography for reference

- Organize components meticulously

- Double-check measurements

Warning: Engine rebuilding requires advanced mechanical skills. If uncertain, consult professional mechanics.

Recommended Reading

- Automotive machine shop manuals

- Specific vehicle service documentation

- Professional engine rebuilding guides