Hit and miss engine governors represent sophisticated mechanical speed control systems that dynamically regulate engine performance through precise centrifugal weight mechanisms. These ingenious devices utilize complex interactions between rotational forces, mechanical linkages, and valve control to maintain consistent engine speed across varying load conditions, making them critical components in early industrial and agricultural power generation technologies.

What Are Hit and Miss Engine Governors?

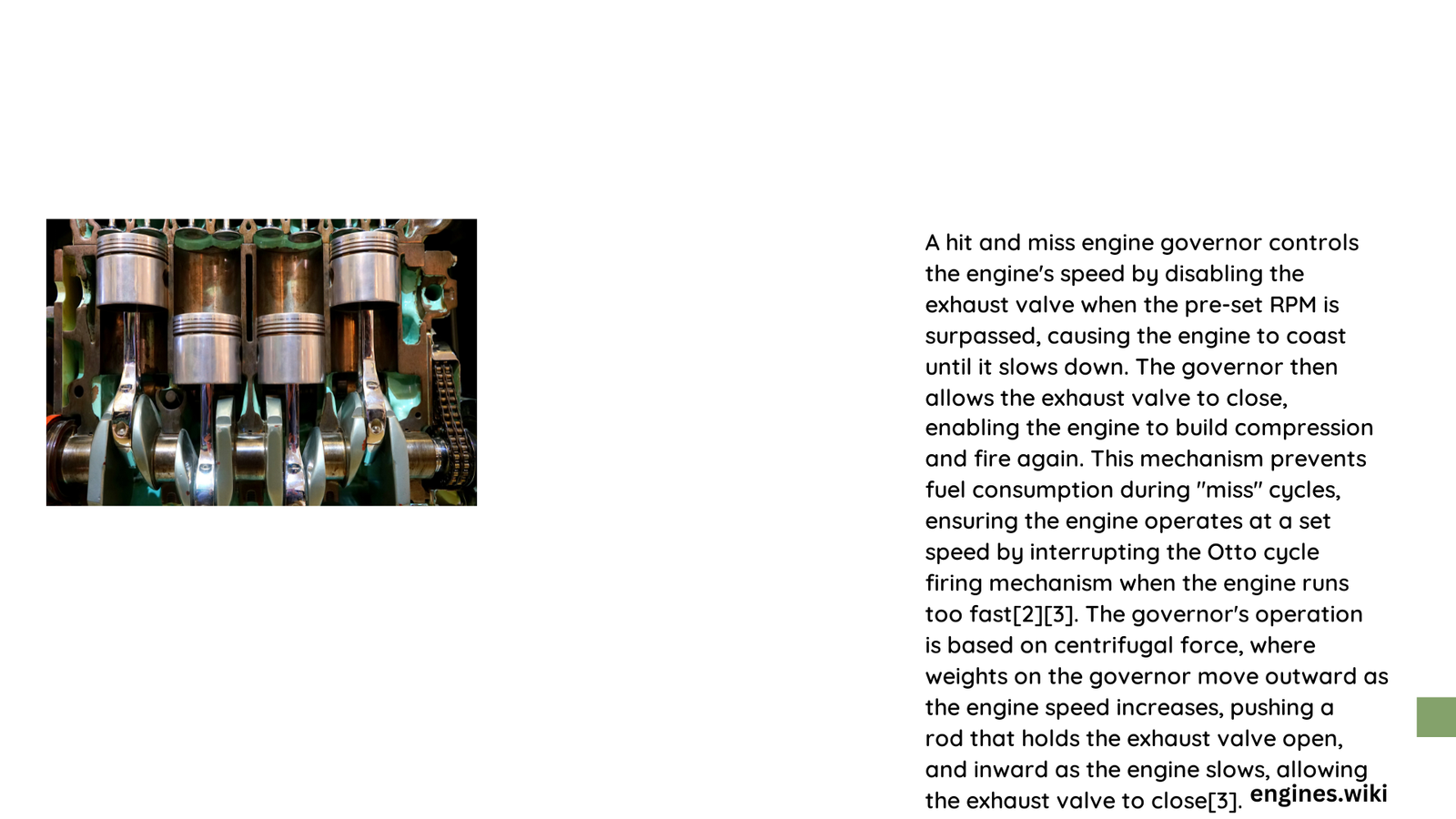

Hit and miss engine governors are mechanical speed control systems designed to maintain consistent engine performance by regulating fuel intake and exhaust valve operation. These governors prevent engine over-speeding by strategically interrupting the engine’s firing sequence when predetermined speed thresholds are exceeded.

How Do Centrifugal Governors Function?

Core Operational Principles

- Weight Movement: Governor weights rotate around a central shaft

- Centrifugal Force Activation: Weights extend outward as engine speed increases

- Mechanical Linkage: Weights trigger exhaust valve control mechanism

| Governor Component | Primary Function | Performance Impact |

|---|---|---|

| Rotating Weights | Speed Detection | Immediate Response |

| Latch Mechanism | Exhaust Valve Control | Speed Regulation |

| Spring Assembly | Tension Management | Precision Adjustment |

What Determines Governor Performance?

Key Performance Factors

- Weight Configuration

- Material composition

- Precise machining tolerances

-

Balanced weight distribution

-

Mechanical Linkage Design

- Lever arm geometry

- Friction reduction

-

Alignment precision

-

Spring Characteristics

- Tension specifications

- Material elasticity

- Fatigue resistance

What Are Common Diagnostic Techniques?

Comprehensive Evaluation Methods

- Visual Inspection

- Check for mechanical wear

- Examine weight movement

-

Verify linkage alignment

-

Performance Testing

- Load variation assessment

- Speed consistency measurement

- Exhaust valve operation analysis

What Replacement Considerations Exist?

Critical Replacement Components

- Governor weights

- Latch mechanism parts

- Tension springs

- Pivot points

- Linkage connectors

What Maintenance Strategies Optimize Performance?

Proactive Maintenance Approach

- Regular lubrication

- Periodic alignment checks

- Precision calibration

- Component wear assessment

- Systematic performance monitoring

What Technical Challenges Emerge?

Potential Operational Limitations

- Mechanical complexity

- Precision manufacturing requirements

- Sensitivity to environmental conditions

- Limited scalability for modern applications

Conclusion

Hit and miss engine governors represent remarkable mechanical engineering achievements, demonstrating sophisticated speed control through ingenious design principles. Their legacy continues to inspire modern control system development across multiple technological domains.

Technical Specifications Summary

- Speed Control Range: 350-600 RPM

- Typical Accuracy: ±5%

- Mean Operational Lifespan: 10-15 years with proper maintenance