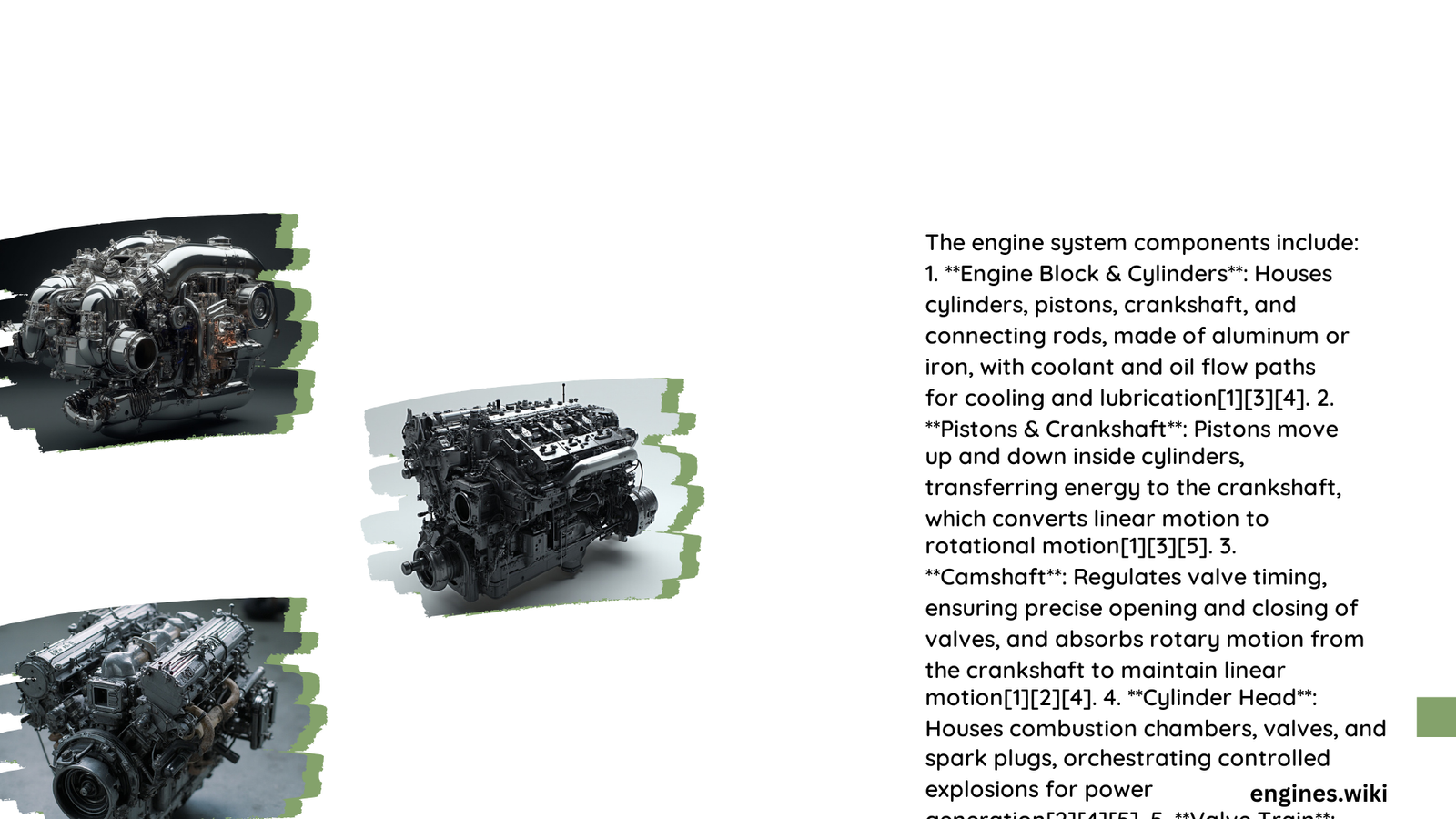

Modern automotive engines are complex systems comprising multiple interconnected components that work harmoniously to convert fuel into mechanical energy. These engine system components include critical parts like the engine block, cylinder head, crankshaft, fuel injectors, and cooling systems, each playing a crucial role in determining vehicle performance, efficiency, and reliability. Understanding these components provides insights into the sophisticated engineering behind automotive powertrains.

What Are the Core Engine System Components?

How Do Engine Blocks Define Structural Integrity?

Engine blocks serve as the fundamental foundation of any internal combustion engine. These critical components provide structural support and house essential mechanical elements. Two primary materials dominate engine block construction:

Cast Iron Blocks

- Exceptional durability

- Reduced thermal expansion

- Weight reduction capabilities up to 30%

- Typical wall thickness: 4.0 to 5.5 mm

Aluminum Alloy Blocks

- Significantly lighter weight

- Superior heat transfer characteristics

- Require additional steel cylinder liners

- More adaptable to modern manufacturing techniques

| Material | Weight | Thermal Conductivity | Durability |

|---|---|---|---|

| Cast Iron | Heavy | Moderate | High |

| Aluminum | Light | High | Moderate |

What Role Do Crankshafts Play in Power Transmission?

Crankshafts transform linear piston motion into rotational energy, serving as the critical link between combustion and mechanical power. Key characteristics include:

- Stroke Length: 70-100 mm range

- Journal Diameter: 50-70 mm

- Material: High-strength steel alloys

- Manufacturing: Precision forging techniques

Crankshaft Performance Factors

- Counterweight design

- Dynamic balancing

- Surface finish

- Material strength

How Do Fuel Injectors Optimize Combustion?

Fuel injectors represent sophisticated fuel delivery mechanisms with two primary configurations:

- Port Fuel Injectors

- Inject fuel into intake manifold

- Flow rates: 15-30 cc/min

-

Wide spray pattern

-

Direct Fuel Injectors

- Inject directly into combustion chamber

- Higher flow rates: Up to 50 cc/min

- Precise spray targeting

What Determines Cylinder Head Efficiency?

Cylinder heads significantly influence engine performance through:

- Airflow Characteristics

- Combustion Chamber Design

- Valve Train Configuration

Key Design Elements

- Port shape and size

- Combustion chamber geometry

- Valve timing mechanisms

- Material composition

How Do Cooling Systems Maintain Thermal Balance?

Cooling systems prevent engine overheating through sophisticated thermal management:

- Wet Liner Configurations

- Integrated Coolant Passages

- Advanced Thermal Spraying Techniques

Cooling Mechanism Types

- Liquid cooling systems

- Air cooling systems

- Hybrid cooling approaches

Technical Insights and Performance Implications

Each engine system component contributes uniquely to overall powertrain performance. Precision engineering, material selection, and advanced manufacturing techniques determine an engine’s efficiency, power output, and longevity.

Performance Optimization Strategies

- Lightweight materials

- Advanced thermal management

- Precision manufacturing

- Computational fluid dynamics modeling

Conclusion

Understanding engine system components provides profound insights into automotive engineering’s complexity. Continuous technological advancements promise more efficient, powerful, and sustainable powertrain solutions.