How an IC Engine Works: Unveiling the Mechanical Marvel

Summary of Internal Combustion Engine Operation

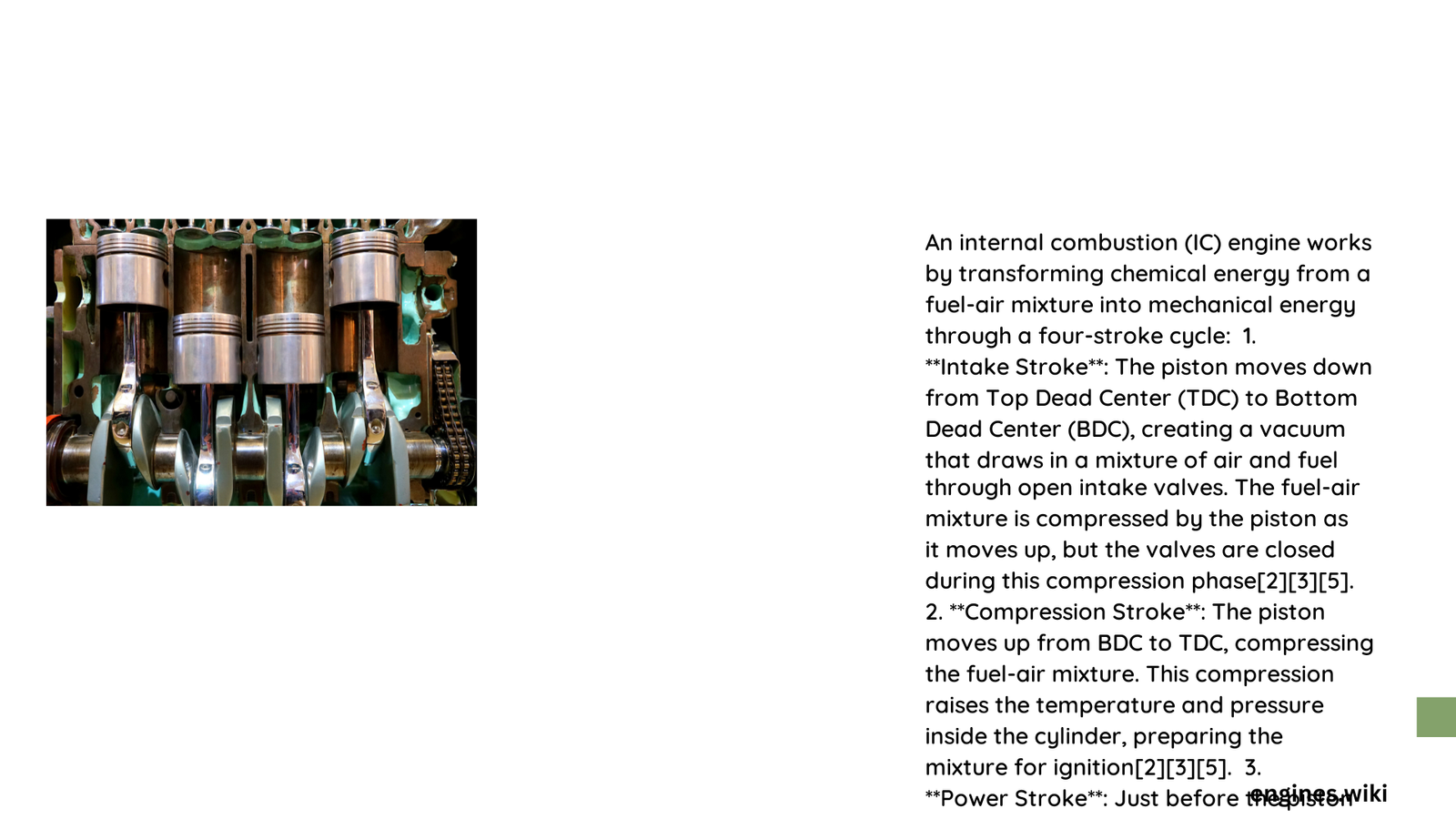

Internal combustion engines transform chemical energy into mechanical power through a precise four-stroke cycle. By converting fuel and air into controlled explosions, these remarkable machines generate rotational force that powers vehicles, generators, and industrial equipment. Understanding the intricate dance of pistons, valves, and combustion processes reveals the engineering brilliance behind modern mechanical propulsion.

What Are the Primary Phases of Engine Operation?

Intake Phase: How Does Air and Fuel Enter the Cylinder?

- The intake stroke begins with the piston moving downward

- Intake valve opens, creating a partial vacuum

- Fuel-air mixture drawn into the cylinder through intake manifold

- Typical pressure range: 0.8-0.9 bar

Key Metrics:

| Parameter | Value |

|———–|——-|

| Intake Valve Timing | Opens before Top Dead Center (TDC) |

| Pressure Range | 0.8-0.9 bar |

| Mixture Composition | Precise air-fuel ratio |

Compression Phase: What Happens When Gases Are Compressed?

- Intake valve closes

- Piston moves upward, compressing fuel-air mixture

- Pressure increases dramatically

- Compression ratio typically 8:1 to 12:1

Compression Effects:

1. Increases mixture temperature

2. Enhances combustion efficiency

3. Prepares for power generation

Power Stroke: How Is Energy Generated?

- Spark plug ignites compressed mixture

- Rapid gas expansion drives piston downward

- Peak pressure reaches 50-60 bar

- Generates primary mechanical energy

Exhaust Phase: How Are Burnt Gases Removed?

- Exhaust valve opens

- Piston moves upward, expelling combustion gases

- Pressure returns to atmospheric levels

- Prepares cylinder for next intake cycle

What Factors Influence Engine Performance?

Fuel-Air Mixture Dynamics

- Optimal air-fuel ratio: 14.7:1

- Precise atomization critical for efficiency

- Electronic fuel injection provides superior control

Ignition Timing Considerations

- Spark timing: 10-30 degrees before Top Dead Center

- Variations impact:

- Power output

- Emissions

- Engine efficiency

What Are Common Engine Challenges?

Performance Limitations

- Compression inefficiencies

- Fuel quality variations

- Mechanical wear

- Heat management

Technical Insights

Efficiency Metrics:

| Performance Indicator | Typical Range |

|———————-|—————|

| Thermal Efficiency | 25-35% |

| Mechanical Efficiency | 80-90% |

| Fuel Conversion | 15-25% |

Advanced Technological Considerations

- Modern engines incorporate:

- Variable valve timing

- Direct fuel injection

- Electronic control units

- Advanced materials

Conclusion

Internal combustion engines represent a complex interplay of thermodynamics, mechanical engineering, and precise control systems. Continuous technological advancements promise increasingly efficient and environmentally friendly propulsion mechanisms.