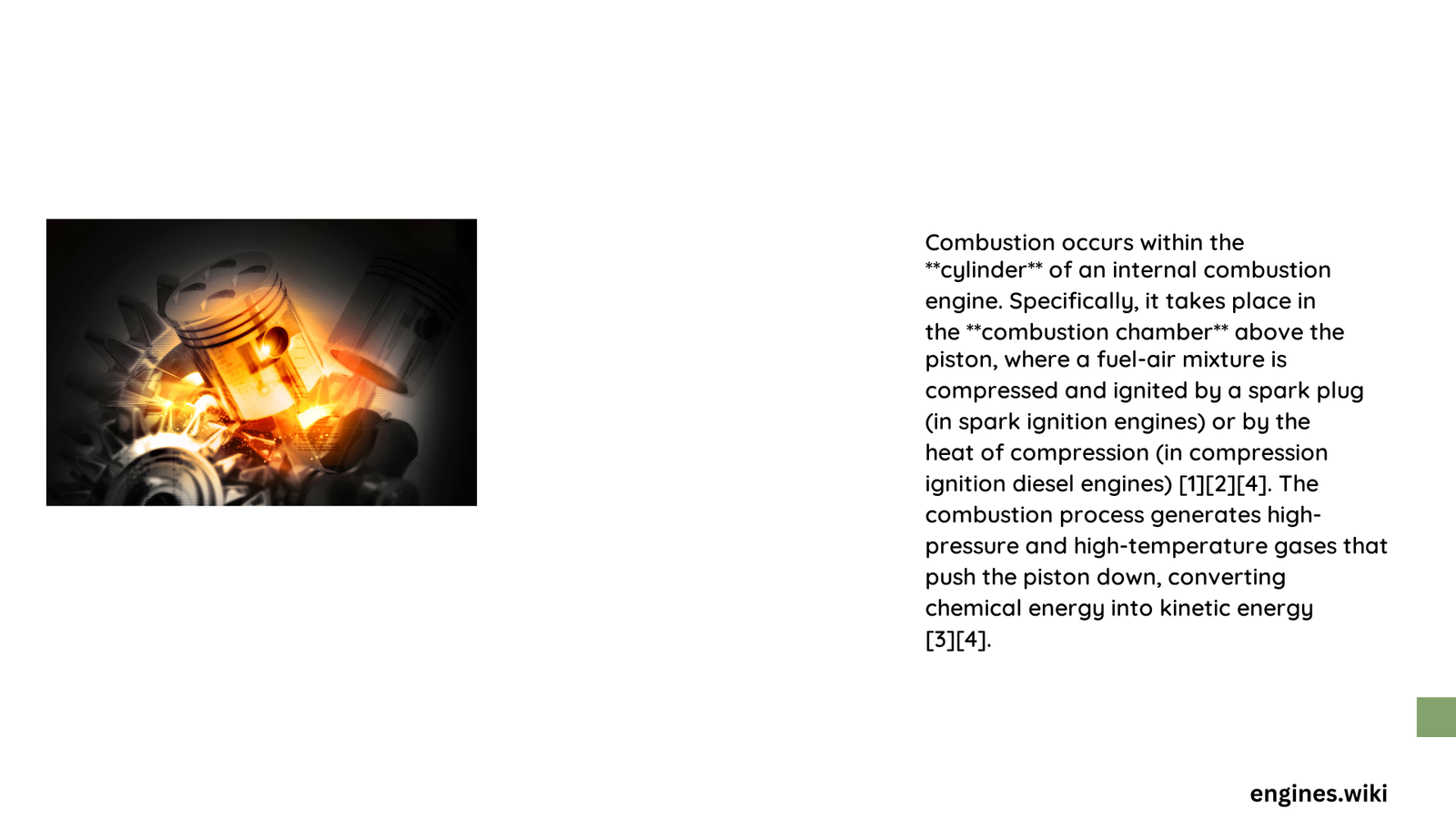

In the intricate world of internal combustion engines, combustion occurs within a specialized region known as the combustion chamber. Located at the top of the cylinder, nestled between the cylinder head and piston, this critical space is where fuel and air transform into explosive energy, driving the mechanical heart of vehicles. The combustion chamber represents a precise engineering marvel where thermodynamic principles convert chemical potential into mechanical motion through controlled, rapid oxidation.

What Makes the Combustion Chamber Unique?

The combustion chamber is not just a simple space but a meticulously designed environment engineered for maximum energy conversion. Its geometry, volume, and structural characteristics play pivotal roles in determining engine performance, efficiency, and power output.

Where Exactly Does Combustion Happen?

Combustion specifically occurs in the confined space above the piston, within the cylinder head’s upper region. This location is strategically chosen to maximize energy transfer and minimize heat loss.

Key Characteristics of Combustion Chambers

| Feature | Description | Significance |

|---|---|---|

| Location | Top of cylinder | Enables direct power transmission |

| Volume | Typically 40-70 cc | Determines compression ratio |

| Shape | Hemi, pent-roof, wedge | Influences combustion efficiency |

How Do Different Engine Types Impact Combustion Location?

- Spark-Ignition Engines

- Combustion occurs near spark plug

- Precise fuel-air mixture required

-

Typical compression ratios: 8:1 to 12:1

-

Diesel Engines

- Combustion happens through compression

- No spark plug needed

- Higher compression ratios: 14:1 to 25:1

What Factors Influence Combustion Efficiency?

Several critical factors determine combustion effectiveness:

- Fuel-Air Ratio: Optimal stoichiometric ratio of 14.7:1

- Compression Ratio: Higher ratios generally improve efficiency

- Chamber Geometry: Promotes turbulence and uniform mixture distribution

- Temperature: Typically ranges between 2,100-2,500°F during combustion

Why Precise Combustion Chamber Design Matters?

Combustion chamber design directly impacts:

– Engine power output

– Fuel efficiency

– Emissions control

– Thermal management

– Mechanical durability

Technological Innovations in Combustion Chambers

Modern engineering has introduced advanced combustion chamber designs:

– Direct injection technologies

– Variable geometry chambers

– Enhanced swirl and tumble mechanisms

– Nano-engineered surface treatments

Challenges in Combustion Chamber Design

Engineers continuously address complex challenges:

– Minimizing heat loss

– Reducing emissions

– Improving fuel atomization

– Managing extreme temperature variations

– Preventing pre-ignition and knocking

Conclusion

The combustion chamber represents a sophisticated intersection of thermodynamics, mechanical engineering, and materials science. Its precise design and location within the engine determine the transformation of chemical energy into mechanical power.